The Impact of Engineering Innovations on Modern Manufacturing

The Evolution of Manufacturing Processes

In recent years, engineering innovations have significantly reshaped the landscape of modern manufacturing. With the dawn of new technologies and methodologies, manufacturers are now able to enhance productivity, reduce costs, and increase product quality. This evolution is not just about adopting new tools but also involves a strategic shift in how production processes are designed and implemented.

One of the most significant changes has been the integration of automation. Automated systems have taken over repetitive tasks, allowing human workers to focus on more complex and creative aspects of production. This not only boosts efficiency but also reduces the likelihood of errors, leading to more consistent and reliable products.

Advanced Materials and Their Benefits

The development of advanced materials has also played a crucial role in modern manufacturing. Materials such as carbon fiber composites, advanced polymers, and metal alloys have opened up new possibilities for product design and functionality. These materials offer benefits like increased strength, reduced weight, and enhanced durability.

For instance, in the automotive industry, the use of lightweight materials has led to the creation of vehicles that are not only more fuel-efficient but also safer. Similarly, in electronics, advanced materials contribute to the production of smaller, more powerful devices.

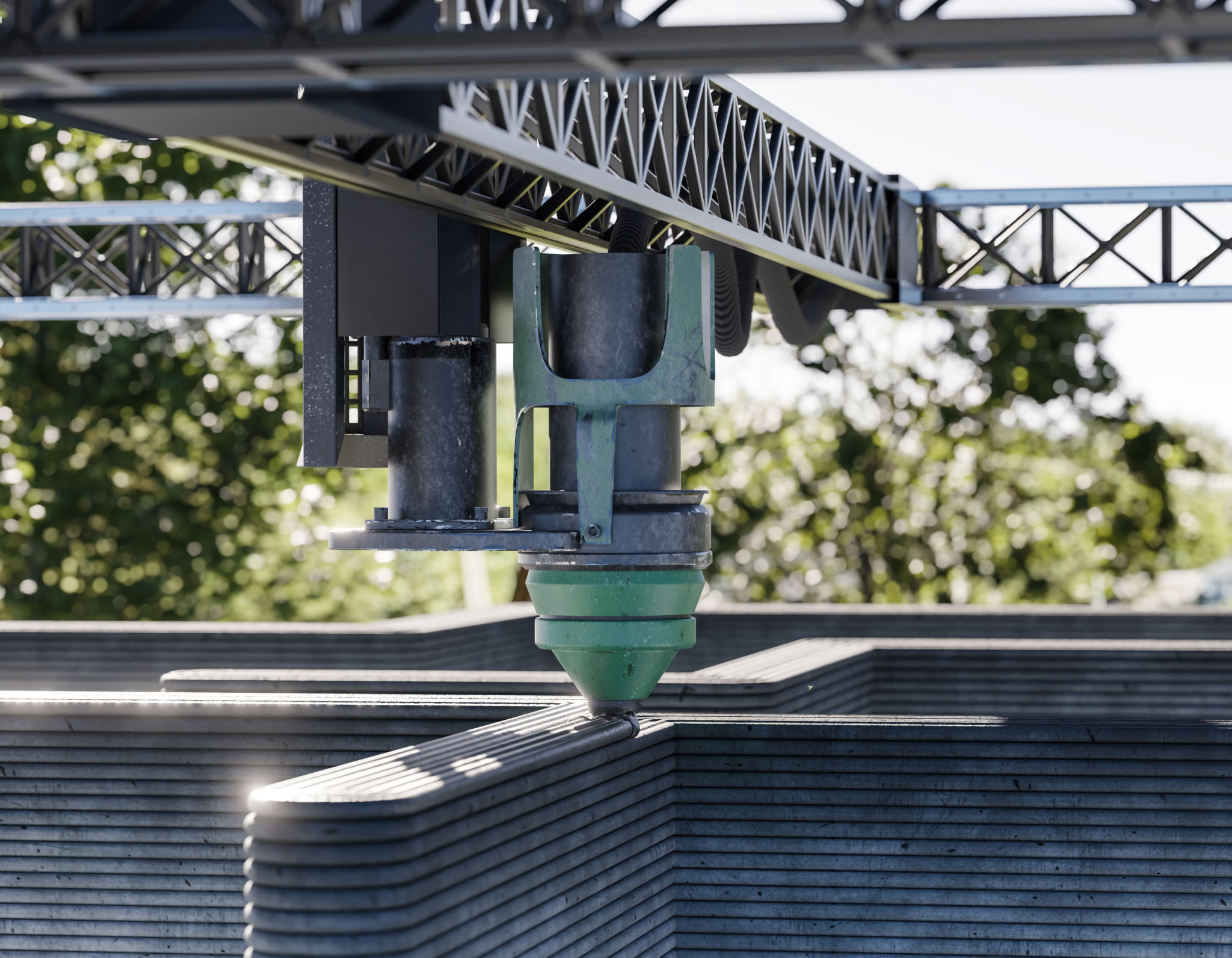

The Role of Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, is another groundbreaking innovation that has transformed the manufacturing sector. This technology allows for the creation of complex geometries that were previously impossible with traditional methods. It also enables rapid prototyping, which significantly shortens the product development cycle.

Moreover, 3D printing supports customization, allowing manufacturers to produce bespoke items tailored to specific customer needs. This capability is particularly beneficial in industries such as healthcare, where customized prosthetics and implants can be produced efficiently.

Smart Factories and IoT Integration

The rise of the Internet of Things (IoT) has led to the development of smart factories. These facilities are equipped with interconnected devices that communicate with each other to optimize production processes. By collecting and analyzing data in real-time, smart factories can make informed decisions that enhance efficiency and reduce waste.

IoT integration also facilitates predictive maintenance, where potential equipment failures are identified before they occur, minimizing downtime and extending the lifespan of machinery. This level of connectivity ensures that manufacturing processes are both agile and resilient.

Sustainability in Manufacturing

Engineering innovations have also contributed to more sustainable manufacturing practices. Companies are now able to implement energy-efficient processes and reduce their carbon footprint. Technologies such as waste recycling systems and resource-efficient machinery play a critical role in promoting sustainability.

Furthermore, the shift towards a circular economy is gaining momentum, where products are designed with their entire lifecycle in mind. This approach not only conserves resources but also encourages the reuse and recycling of materials.

In conclusion, engineering innovations are driving significant changes in modern manufacturing. From automation and advanced materials to additive manufacturing and IoT integration, these developments are paving the way for a more efficient, customizable, and sustainable industry. As technology continues to evolve, manufacturers must stay adaptable and forward-thinking to harness these innovations effectively.